|

| December 10, 2013 | Volume 09 Issue 46 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Automotive Materials:

Lightweight steel twist beam achieves 30 percent mass reduction, lower costs

Keeping with its mission to help automakers meet stringent fuel economy requirements, the Steel Market Development Institute's (SMDI) Automotive Applications Council unveiled the results of its lightweight steel twist beam study on Dec. 4, 2013.

The project resulted in a 30 percent mass reduction at a significantly lower cost compared to designs using alternative materials. SMDI is a business unit of the American Iron and Steel Institute.

"With fuel economy regulations increasing rapidly, automakers are looking for every way they can to take weight out of vehicles," said Ronald Krupitzer, vice president, Automotive Market, SMDI. "The lightweight steel twist beam project is a great example of how currently available advanced steel technologies enable aggressive weight savings in the vehicle's suspension, thus enabling better fuel economy for the automaker and the consumer."

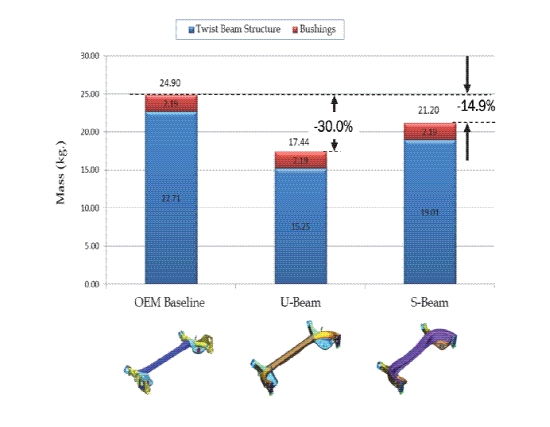

The results of the study indicated that the selected "U-Beam" design, based on a tubular shape using advanced steels, achieves a 30 percent mass reduction relative to the baseline assembly at a modest 15 percent cost increase -- considerably less than the cost of similar weight savings from materials like aluminum.

The original objective of the project was to develop a lightweight steel twist beam that achieved 15 to 25 percent mass reduction, with equivalent performance to the baseline design and a lower or equivalent cost to alternative materials. A twist beam assembly in commercial use today was selected for the baseline packaging, performance, mass, and cost.

Funded by members of SMDI's Automotive Applications Council and members of Chrysler Group, LLC, Ford Motor Co., and General Motors Co., the lightweight twist beam project was conducted by Ontario, Canada-based Multimatic Inc. For a copy of the final report, click here. Note: This report pdf may take a moment to load.

Source: SMDI

Published December 2013

Rate this article

View our terms of use and privacy policy